Blog

Hand Tools Are Essential Features and Best Practices to Maximize Efficiency in Your Operations

In the world of manufacturing and construction, the importance of efficiency cannot be overstated. According to a report by the National Institute for Occupational Safety and Health (NIOSH), the use of proper hand tools can lead to increased productivity by as much as 20% in industrial operations. Hand tools are essential features that streamline tasks, enhance precision, and reduce physical strain on workers. A recent survey by the Bureau of Labor Statistics also indicates that jobs utilizing hand tools report lower injury rates, showcasing not only their functional benefits but also their role in promoting workplace safety.

As industries continue to prioritize efficiency and safety, understanding the best practices surrounding hand tool usage becomes paramount. Companies that incorporate ergonomic designs and tailored training programs witness a significant improvement in their operational outcomes. In fact, a study by the Occupational Safety and Health Administration (OSHA) reveals that implementing best practices for hand tool management can decrease job-related injuries by up to 50%. This blog will explore how hand tools are indispensable for maximizing efficiency in various operations, and provide insights into industry best practices that can help organizations leverage these tools effectively.

The Importance of Hand Tools in Modern Work Environments

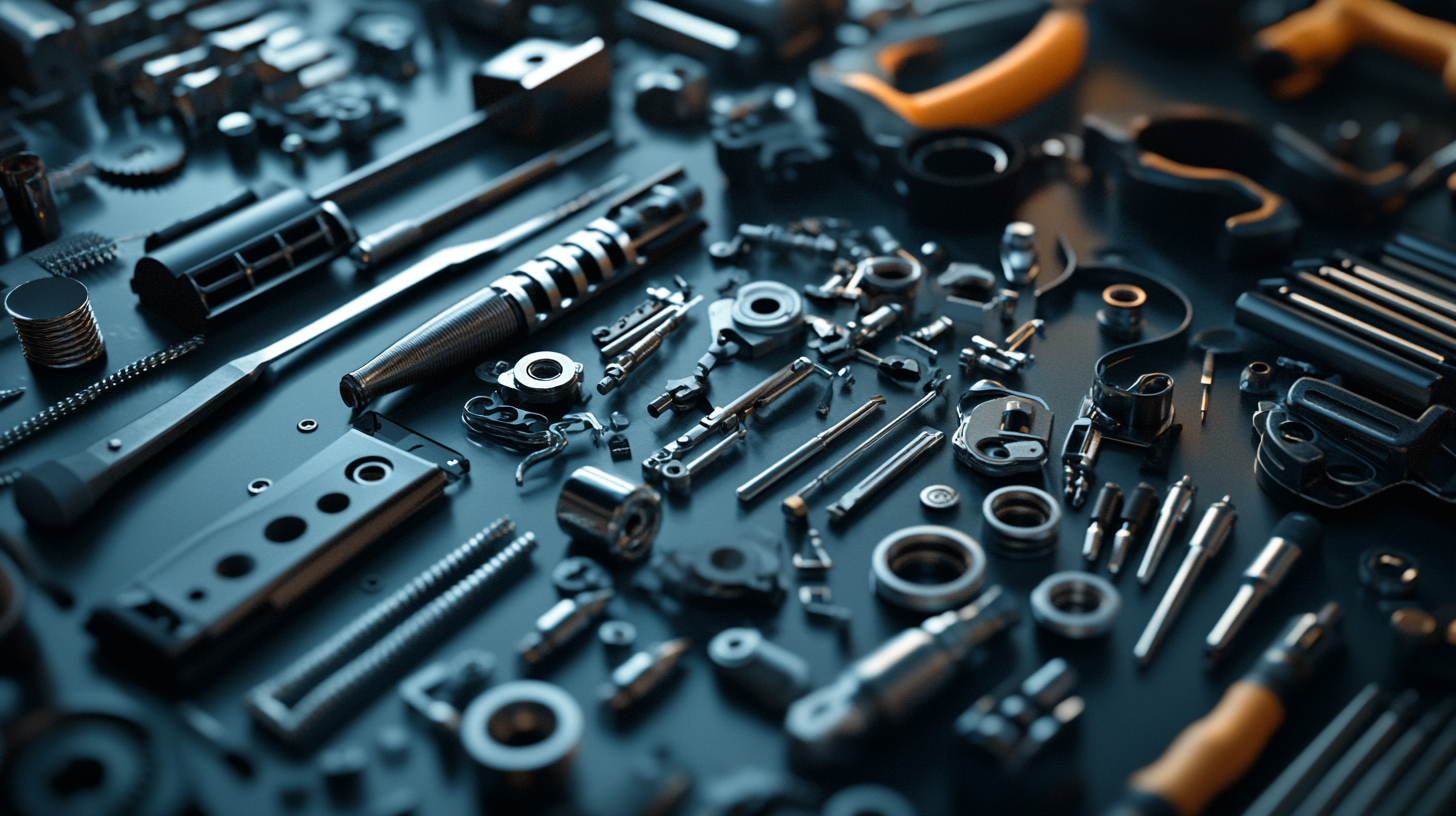

In modern work environments, hand tools play an indispensable role that extends beyond mere functionality. As organizations increasingly embrace cloud computing and innovative technologies, the integration of hand tools in various operations has proven essential for maintaining efficiency and productivity. According to the 2023 China Cloud Office Industry Research Report, the shift towards cloud-based systems has directly influenced operational practices, highlighting the need for practical tools that can enhance workforce effectiveness. The significance of hand tools is evident in environments where precision and adaptability are paramount. A recent analysis revealed that businesses that prioritize the use of hand tools alongside advanced technologies report a 30% increase in operational efficiency. This integration allows teams to tackle tasks that require a personal touch while leveraging cloud applications for data management and communication. Hand tools not only complement digital solutions but also foster creativity and problem-solving among workers, making them vital assets in achieving high-quality outputs. Moreover, the importance of hand tools in the context of new production capacities cannot be overstated. As emphasized by President Xi Jinping, developing new quality productivity is a critical requirement for driving high-quality development. In this landscape, equipping teams with the right hand tools ensures that they can respond agilely to evolving demands. Ultimately, the synergy between hand tools and modern technological infrastructures is key to unlocking new levels of productivity and innovation in today’s dynamic work environment.

Key Features of Efficient Hand Tools: What to Look For

When selecting hand tools for your operations, understanding the key features that contribute to their efficiency is crucial. One of the most important aspects to consider is ergonomics. Tools designed with ergonomic handles reduce strain on the hands and wrists, allowing for prolonged use without discomfort. Look for tools that fit comfortably in your grip, as this can significantly enhance your productivity and reduce the risk of injuries.

Another vital attribute is the weight and balance of the tool. A well-balanced tool minimizes fatigue, increasing the time you can work effectively. Heavier tools might seem sturdy, but if they are cumbersome, they can slow you down and hinder precision. Opt for tools that provide the perfect balance of strength and lightweight construction, ensuring maximum maneuverability without compromising on durability.

Durability also plays a key role in the long-term efficiency of hand tools. Select tools made from high-quality materials that can withstand rigorous daily use. Features such as rust-resistant coatings and reinforced designs can extend the lifespan of your tools, saving you money and time on replacements. Additionally, tools that are easy to maintain will help keep your operations running smoothly, as they require less downtime for repairs or upkeep.

Best Practices for Organizing and Maintaining Hand Tools

In today's fast-paced work environment, effectively organizing and maintaining hand tools is crucial not only for maximizing productivity but also for minimizing waste—something all organizations should strive to eliminate. Just as integrating artificial intelligence into various business processes can optimize efficiency and drive growth, a well-structured approach to hand tool management can significantly enhance operational workflows. By categorizing tools and implementing a systematic storage solution, employees can easily access the right tools for the job, reducing time spent searching and increasing overall work quality.

Furthermore, the practice of maintaining hand tools in peak condition ensures that they remain effective and safe to use. Regular checks, cleaning, and proper storage can prevent tool failure, which can lead to work delays and unintended costs. Similar to the need for compliance and risk management in AI implementation, ensuring that tools are maintained also protects the business’s physical resources and upholds safety standards.

Integrating technology into tool management, such as using inventory management software or apps, can enhance organization and tracking. This not only streamlines access to tools but also allows for better forecasting of repair needs and inventory levels, much like how AI offers insights into operational metrics. By embracing both traditional hand tool practices and modern organizational techniques, businesses can create an efficient ecosystem that fuels productivity and reduces operational waste.

Maximizing Productivity: Workflow Strategies with Hand Tools

Maximizing productivity in any operation often hinges on the effective use of hand tools. These tools, ranging from basic hammers and screwdrivers to specialized pliers and wrenches, are crucial for a variety of tasks. To enhance workflow, it's essential to understand not just how to use these tools, but when and where they can be most effective. Implementing a systematic approach to tool selection can significantly reduce time spent on tasks, allowing workers to focus on precision rather than mere execution.

Organizing tools in a logical manner further contributes to efficiency. Creating designated workspaces and using toolboxes or stations tailored to specific tasks can minimize unnecessary movement and time waste. This enables teams to access required tools swiftly, promoting a seamless workflow. Additionally, training employees in tool handling and safety practices ensures that everyone is familiar with the best procedures, which not only boosts confidence but also decreases the likelihood of errors that can disrupt productivity.

Emphasizing a culture of maintenance is also vital to maximizing the benefits of hand tools in operations. Regularly inspecting and servicing tools ensures they function optimally, reducing downtime caused by equipment failure. Furthermore, encouraging workers to provide feedback on tools and workflows fosters an environment of continuous improvement, paving the way for innovative solutions that enhance productivity and streamline operations. By prioritizing these strategies, organizations can effectively leverage the power of hand tools to achieve their operational goals.

Innovative Techniques to Enhance Hand Tool Effectiveness

In today's fast-paced industrial environment, maximizing the efficiency of hand tools is paramount for operational success. Innovative techniques can indeed enhance the effectiveness of these essential implements. According to a report from the National Safety Council, improper use of hand tools contributes to roughly 20% of all workplace injuries, highlighting the need for better practices and training. To mitigate these risks and boost productivity, introducing systematic training programs on proper tool usage is crucial.

One innovative approach is the implementation of ergonomic designs in hand tools. Research by the American National Standards Institute has shown that tools designed with ergonomics in mind can reduce user fatigue by up to 50%, leading to longer and more efficient work sessions. For example, the use of cushioned grips and lightweight materials can significantly lessen strain on the hands and wrists, allowing workers to perform tasks more effectively over extended periods.

Additionally, utilizing technology for inventory management can also streamline operations. According to a survey conducted by the Manufacturing Institute, organizations that leverage digital tools for tracking hand tools see a 15% decrease in tool loss and improved workflow efficiency. This can be achieved through barcoding systems or mobile apps that allow workers to check tools in and out seamlessly, ensuring that every tool is accounted for and available when needed.