Blog

Unmatched Manufacturing Excellence from Premier Chinese Factories as Your Top Tools Supplier

In today's competitive market, the quest for superior-quality tools has led many businesses to seek out the best tools suppliers, and one region stands out for its unmatched manufacturing excellence - China. Known for its advanced production capabilities, Premier Chinese factories have become the go-to source for top-tier tools that meet strict industry standards. These suppliers not only offer a diverse range of innovative products tailored to various applications but also ensure that quality control processes are integral to their operations. By collaborating with these manufacturers, companies can harness the benefits of cost-effective production while maintaining high standards of durability and performance. This blog will explore the myriad advantages of partnering with reputable Chinese tools suppliers, highlighting how their exceptional craftsmanship and technological advancements can elevate your operational efficiency and competitiveness in the marketplace.

Unveiling the Technical Specifications of Top Tools from Leading Chinese Manufacturers

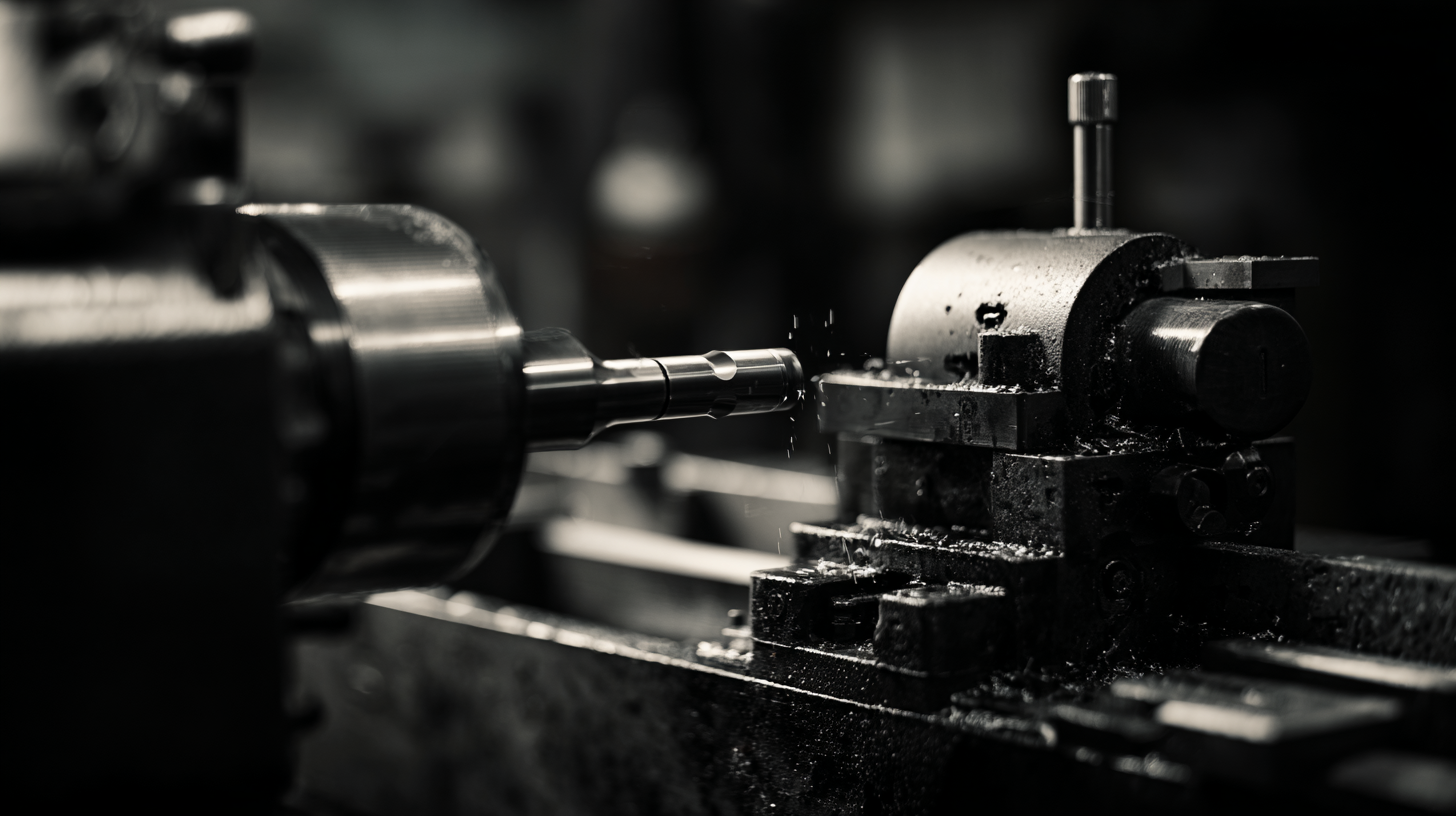

When it comes to sourcing tools, Premier Chinese factories stand out due to their commitment to quality and innovation. The technical specifications of the tools produced by these leading manufacturers reflect a meticulous attention to detail and advanced engineering practices. Take, for instance, precision machining tools that boast extremely low tolerances, ensuring accuracy and reliability in every application. These tools often feature high-speed steel or carbide materials that enhance durability and performance, setting a high standard in the marketplace.

In addition to precision, many of these tools are designed for user-centric performance, incorporating ergonomic features that reduce fatigue during prolonged use. For example, impact wrenches with lightweight designs and vibration-dampening technology not only enhance efficiency but also prioritize user comfort. Furthermore, the integration of smart technology in many tools allows for real-time performance monitoring and diagnostics, ensuring that users can maintain optimal operational effectiveness. This blend of technical sophistication and user-focused design positions these tools from top Chinese manufacturers as exemplary choices for industries seeking unmatched performance and reliability.

Tool Quality Comparison from Leading Chinese Manufacturers

Understanding the Quality Assurance Standards in Premier Chinese Factories

In today’s manufacturing landscape, quality assurance has become a critical factor that distinguishes leading suppliers, particularly in Chinese factories. According to a report by McKinsey & Company, nearly 70% of manufacturers are enhancing their quality control measures to align with global standards. This strategic shift is driven by the increasing demand for high-quality tools and products, which has prompted premier Chinese factories to adopt stringent quality assurance protocols such as ISO 9001 and Six Sigma methodologies.

Moreover, a survey conducted by Deloitte revealed that 61% of manufacturers view quality assurance as a major priority in supply chain management. This focus not only enables factories to minimize defects but also enhances customer satisfaction by ensuring product reliability. By investing in advanced technologies and thorough training programs, Chinese manufacturers are adeptly bridging the gap between cost-efficiency and exceptional product quality, making them formidable contenders in the tools supply industry. This concerted effort to meet and exceed global quality assurance standards positions these factories as top-tier suppliers in a competitive market.

Unmatched Manufacturing Excellence from Premier Chinese Factories

| Factory Location | Product Category | Quality Assurance Certification | Production Capacity (Units/Month) | Lead Time (Days) |

|---|---|---|---|---|

| Shenzhen | Electronics | ISO 9001 | 50000 | 30 |

| Dongguan | Textiles | OEKO-TEX | 30000 | 25 |

| Suzhou | Automotive Parts | IATF 16949 | 20000 | 45 |

| Hangzhou | Consumer Goods | ISO 9001 | 40000 | 20 |

| Ningbo | Kitchen Appliances | CCC | 15000 | 35 |

Key Performance Metrics: Evaluating Tools for Durability and Efficiency

When evaluating tools for durability and efficiency, it's essential to focus on key performance metrics that truly matter in a manufacturing context. Chinese factories are rapidly becoming leaders in producing high-quality tools by utilizing advanced materials and innovative designs. A crucial metric to consider is the longevity of a tool under extreme conditions. Tools that can withstand rigorous usage without compromising performance are invaluable for any operation.

Another important aspect to evaluate is the efficiency of the tools during the manufacturing process. This encompasses not just the speed of use but also how they enhance overall productivity. Tools that minimize downtime and allow for quick adjustments can significantly impact the output of a manufacturing line. Moreover, assessing the energy consumption of tools indicates their efficiency, making it easier to identify those that not only perform well but are also cost-effective over time. By focusing on these performance metrics, manufacturers can choose tools that truly elevate their operational excellence.

The Role of Advanced Technologies in Enhancing Manufacturing Processes

In the rapidly evolving landscape of manufacturing, advanced technologies have become the cornerstone of operational excellence.

Chinese factories, renowned for their innovative approaches, are leveraging state-of-the-art machinery and streamlined processes to enhance their production capabilities.

Automation, robotics, and artificial intelligence are not just buzzwords; they are the driving forces behind the efficiency and precision that modern manufacturing demands.

By integrating these technologies, factories can reduce errors, speed up production times, and ultimately deliver superior products to their clients.

Moreover, the role of data analytics in manufacturing cannot be overlooked.

By harnessing big data, manufacturers can gain valuable insights into their processes, allowing for real-time monitoring and adjustments.

This proactive approach not only minimizes downtime but also optimizes resource allocation and reduces waste.

As Chinese factories continue to embrace such advanced technologies, they position themselves as premier tools suppliers that can meet the diverse needs of industries worldwide, setting new standards for quality and innovation.

How to Choose the Right Tools Supplier: Insights from Industry Leaders

In the ever-evolving landscape of the hand tools market, selecting the right tools supplier is crucial for businesses aiming for manufacturing excellence. According to the latest market analysis, the global hand tools market is expected to grow significantly, with estimates projecting a compound annual growth rate of approximately 5.5% through 2025. This surge underscores the increasing demand for high-quality tools and the vital role played by reliable suppliers in meeting these needs.

Industry leaders emphasize the importance of evaluating potential suppliers based on vital criteria such as product quality, innovation capabilities, and customer service. As highlighted in the recent insights from Evan Zeng, a senior research director at Gartner, understanding market dynamics and supplier performance is essential for informed decision-making. The impact of COVID-19 has further accelerated the pivot towards online platforms, compelling suppliers to enhance their digital presence and streamline logistics to maintain competitiveness in the post-pandemic era. Selecting a supplier that not only offers exceptional products but also adapts to market challenges can significantly influence a business's operational success.