Blog

7 Innovative Uses of Hand Tools in Modern Industries: 5 Reasons They’re Essential for Every Workshop

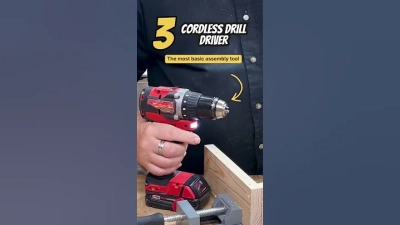

In today's fast-paced industrial landscape, where technology often takes center stage, hand tools remain indispensable for a multitude of reasons. The versatility and precision offered by hand tools make them essential in various sectors, from construction to woodworking and automotive repair. As we delve into the innovative uses of these tools, we'll explore how they not only enhance productivity but also foster creativity and craftsmanship. Moreover, the unique tactile experience provided by hand tools allows artisans and workers to connect more intimately with their projects, resulting in superior outcomes. In this blog, we will highlight seven innovative applications of hand tools in modern industries and discuss five compelling reasons why they should be an integral part of every workshop. Whether you're a seasoned professional or a DIY enthusiast, the continued relevance of hand tools in a technology-driven world cannot be overstated.

Creative Applications of Hand Tools in Contemporary Manufacturing

Hand tools have seen a resurgence in modern manufacturing, offering innovative applications that enhance productivity and creativity in workshops. Despite the advancements in power tools and automation, hand tools remain essential for precision tasks that require human dexterity and meticulous attention to detail. Their portability and ease of use make them invaluable in settings where flexibility and adaptability are paramount. From ergonomic designs that reduce fatigue to specialized tools catering to niche applications, the creative applications of hand tools are limitless.

Moreover, as industries increasingly integrate artificial intelligence into their workflows, hand tools complement this evolution by allowing workers to engage more intimately with their tasks. Hand tools facilitate a hands-on approach that helps in identifying issues and ensuring quality control, which is sometimes overlooked with larger machinery. This harmonious balance between advanced technology and traditional craftsmanship could pave the way for new efficiencies and innovative manufacturing processes, demonstrating that the humble hand tool is far from obsolete in today’s rapidly changing industrial landscape.

Innovative Uses of Hand Tools in Modern Industries

This bar chart illustrates the percentage of innovative hand tool applications across various modern industries. As depicted, metalworking and construction exhibit the highest utilization of hand tools, showcasing their essential role in contemporary manufacturing processes.

Essential Hand Tools for Precision and Accuracy in Crafting

In the world of modern industries, hand tools remain indispensable for achieving precision and accuracy in crafting. These tools, often overlooked in favor of advanced machinery, provide artisans with the tactile feedback and control necessary to produce high-quality work. From chisels and hand planes to precise measuring devices, each tool plays a vital role in enhancing the intricacies of craftsmanship. The ability to fine-tune details by hand often leads to a superior finish that machines struggle to replicate, enabling artisans to meet the unique demands of custom projects.

Moreover, the use of hand tools fosters a deeper connection between the craftsman and their work. The physicality of using hand tools allows craftsmen to feel every nuance of the material, leading to more intuitive decision-making processes. This hands-on approach not only enhances the quality of the final product but also encourages creativity and innovation. As industries evolve, integrating traditional hand tools with modern applications empowers craftsmen to push boundaries, ensuring precision and accuracy while retaining a personal touch in every piece they create.

7 Innovative Uses of Hand Tools in Modern Industries

| Application | Industry | Essential Tool | Reason for Importance |

|---|---|---|---|

| Precision Fitting | Construction | Tape Measure | Ensures accurate measurements for structural integrity |

| Wood Shaping | Carpentry | Chisel Set | Produces customized shapes and designs |

| Metalworking | Manufacturing | Hand File | Essential for finishing and smoothing metal surfaces |

| Surface Leveling | Landscaping | Level | Ensures even surfaces for installations |

| Textile Cutting | Fashion | Tailor Scissors | Provides clean and precise cuts for garments |

| Circuit Board Assembly | Electronics | Tweezers | Handles small components with precision |

| Stone Cutting | Masonry | Masonry Hammer | Critical for shaping and fitting stones seamlessly |

How Hand Tools Enhance Safety and Ergonomics in the Workplace

In modern industries, hand tools are not merely traditional implements; they represent an essential component of workplace safety and ergonomics. According to data from the National Institute for Occupational Safety and Health (NIOSH), overexertion injuries account for a significant percentage of workplace incidents. Utilizing ergonomic hand tools can help reduce these risks by minimizing strain on workers’ bodies, allowing for a more comfortable posture during use. Innovative designs that align with the user's natural movements can significantly reduce fatigue and improve productivity, emphasizing the crucial role that hand tools play in maintaining a safer work environment.

Furthermore, the advent of technologies like "hand-eye tracking" in interactive environments enhances the way workers engage with tools. As reported, these advanced systems allow users to interact with their tasks in a more intuitive manner, bringing efficiency and precision to operations. By integrating hand tools with ergonomic designs and the latest interactive technologies, industries can enhance not only safety but also overall job satisfaction. Studies show that when workers feel comfortable and safe, their productivity can increase by up to 20%, further solidifying the importance of hand tools in contemporary workshops and workplaces.

Sustainable Practices: Hand Tools versus Power Tools in Industries

In today's industrial landscape, the debate between hand tools and power tools is increasingly relevant as industries seek to adopt sustainable practices. According to a report from the National Institute of Standards and Technology (NIST), hand tools can significantly reduce energy consumption within manufacturing processes. For instance, using hand tools over power tools can decrease energy usage by up to 30%, especially in assembly lines where precision and control are paramount. This efficiency not only lowers operational costs but also diminishes the carbon footprint associated with energy production.

Moreover, incorporating hand tools into workshops supports a culture of craftsmanship and skill development. The Bureau of Labor Statistics (BLS) reported that industries relying on skilled trades are seeing a resurgence in demand for workers proficient in manual traditions. This shift is attributed to the increasing complexity of projects that require nuanced touch—something that power tools often lack. Furthermore, by prioritizing hand tools, companies can foster a safer work environment, as they typically present lower risks of injury compared to their powered counterparts, leading to decreased workplace accidents and improved employee well-being.

Ultimately, while power tools undoubtedly play a crucial role in modern industries, the resurgence of hand tools presents a compelling argument for blending both in pursuit of sustainable, skilled, and safer practices.

The Role of Hand Tools in Skill Development and Craftsmanship Today

In today's fast-paced world, the resurgence of traditional craftsmanship highlights the significance of hand tools in skill development and personal growth. As noted in recent discussions, mastering the fine art of hand tools not only cultivates technical abilities but also fosters a deep connection to the craftsmanship. This echoes the thoughts of Socrates, who believed that the essence of humanity lies in our capacity to handle and manipulate our surroundings. By honing our skills with these tools, we engage in a process of self-improvement, making the act of creation as much about personal development as it is about producing tangible objects.

Moreover, the art of hand tool usage fosters creativity and critical thinking, essential components in today's industries. As young blacksmiths revive ancient forging techniques, they exemplify how traditional skills can be adapted to modern contexts, leading to innovative applications across various fields. Hand tools demand a level of precision and care that machinery often overlooks, encouraging a more thoughtful approach to craft. As industries increasingly recognize the value of these skills, the importance of hand tools becomes clear – they are not merely instruments but gateways to mastery, creativity, and sustainable craftsmanship in the contemporary landscape.