Blog

2026 How to Choose the Right Polyurethane Adhesive Sealant?

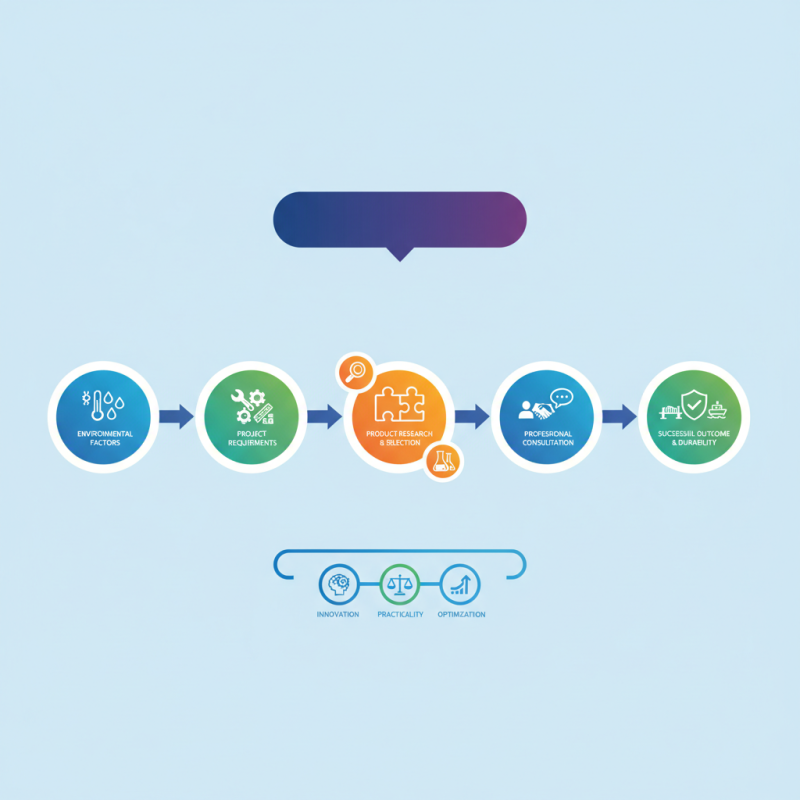

Choosing the right Polyurethane Adhesive Sealant can be challenging. Many factors influence this decision. Different projects require specific properties in a sealant. Understanding these needs can lead to a successful outcome.

Polyurethane Adhesive Sealant is known for its durability and flexibility. It can bond various materials, from wood to metal. However, not all sealants are created equal. Some may fail under certain conditions. Choosing the wrong one could result in leaks or structural issues.

Consider the environment in which the sealant will be used. Is it exposed to extreme temperatures or moisture? Assessing these factors helps narrow down your options. Trial and error can lead to mistakes. Therefore, research is vital. You should explore different brands and formulations. Engaging with professionals can provide insights. Ultimately, the goal is to find a sealant that meets your specific needs. Balancing innovation with practicality is key.

Understanding Polyurethane Adhesive Sealants

Polyurethane adhesive sealants are vital in construction and manufacturing. They provide strong bonding and sealing capabilities, making them popular. According to a report by Freedonia Group, the global demand for adhesive sealants is projected to grow by 4.5% annually, reaching $11 billion by 2026. Understanding the properties of polyurethane sealants helps in making informed choices.

These sealants exhibit excellent flexibility and durability. Their ability to withstand extreme temperatures and UV exposure is noteworthy. They bond well to various materials, such as metal, glass, and plastics. However, not all polyurethane sealants are the same. Some may not cure correctly in humid conditions or may become brittle over time. This inconsistency can lead to challenges in applications.

When choosing a polyurethane adhesive sealant, consider factors like curing time, application method, and environmental conditions. Ensure it fits the specific project's requirements. According to a study from Research and Markets, improper application can lead to a failure rate of over 30% in the field. Knowledge and careful selection can mitigate these risks significantly.

2026 How to Choose the Right Polyurethane Adhesive Sealant?

This chart demonstrates the popularity of different types of polyurethane adhesive sealants based on their application areas in 2026.

Types of Polyurethane Adhesive Sealants Available

When selecting a polyurethane adhesive sealant, it's crucial to understand the types available. These sealants fall into various categories based on their application and properties. Structural sealants, for instance, offer high strength and durability, making them ideal for demanding applications. They undergo rigorous testing and can withstand extreme weather conditions. Reports indicate that structural sealants can hold up to 400 psi in tensile strength, providing reliable adhesion for both construction and automotive industries.

Another type to consider is the non-structural adhesive sealant. This option is more flexible and suitable for areas requiring movement, such as joints and seams. These sealants typically have lower tensile strength, often below 100 psi. However, they excel in providing waterproof barriers. Industry data shows a growing trend in demand for non-structural sealants, particularly in residential construction.

Lastly, hybrid polyurethane sealants combine features of traditional sealants with silicone characteristics. While they offer versatility, users often report challenges in adhesion to certain surfaces. This combination can lead to inconsistencies, urging users to conduct tests before large-scale applications. Understanding these nuances can streamline the selection process and enhance project outcomes.

2026 How to Choose the Right Polyurethane Adhesive Sealant? - Types of Polyurethane Adhesive Sealants Available

| Type | Description | Best Uses | Curing Time | Temperature Resistance |

|---|---|---|---|---|

| One-Part Polyurethane | Easy to apply and cures on exposure to moisture. | Construction, automotive, and general sealing. | 24 hours | -40°C to 90°C |

| Two-Part Polyurethane | Requires mixing of a resin and a hardening agent. | Heavy-duty applications, structural bonding, and automotive repairs. | Varies, typically 24-48 hours | -40°C to 120°C |

| Low-VOC Polyurethane | Environmentally friendly with reduced volatile organic compounds. | Indoor applications where air quality is a concern. | 12-24 hours | -30°C to 100°C |

| Flexible Polyurethane | Allows for movement and is ideal for joints. | Expansion joints, flooring, and roofing. | 24 hours | -50°C to 90°C |

Key Features to Consider When Choosing Sealants

When selecting a polyurethane adhesive sealant, it's essential to focus on key features that meet your specific needs. One important consideration is the sealant's adhesion properties. According to the Adhesive and Sealant Council, polyurethane sealants provide excellent bonding on various substrates. This versatility makes them suitable for diverse applications.

Another vital feature to evaluate is the cure time. Some polyurethane sealants cure quickly, while others take longer. The right choice depends on your project's timeline. Additionally, consider the sealant's flexibility. A good polyurethane sealant should maintain elasticity after curing. Research reveals that sealants with higher flexibility withstand temperature fluctuations better, which is crucial in many environments.

Tips: Always test a small area first. Not all surfaces respond the same way. Monitoring factors like temperature and humidity can affect the curing process. Make sure to check the sealant’s resistance to UV light and chemicals as well. These properties will dictate the longevity and durability of your application. Don’t overlook the importance of proper surface preparation. Inadequate surface treatment can lead to poor adhesion and eventual failure.

Applications of Polyurethane Sealants in Various Industries

Polyurethane sealants find applications across various industries due to their versatility and effectiveness. In construction, they can seal joints in concrete and masonry. These sealants resist moisture and temperature fluctuations, making them ideal for both indoor and outdoor use. They bond well with different materials like wood, metal, and glass, providing long-lasting durability.

In automotive manufacturing, polyurethane sealants are crucial for assembling components. They can insulate and protect against vibrations. This contributes to vehicle durability while enhancing energy efficiency. The aerospace industry also relies on these sealants for aircraft assembly. Their ability to withstand extreme conditions is vital here.

**Tips:** Choosing the right sealant can be daunting. Always check compatibility with the surfaces you plan to use. Perform a small test if possible. Also, consider application conditions like temperature and humidity. Ensure a clean surface for the best adhesion. Remember, not all sealants work the same way. This might require some trial and error.

Best Practices for Using Polyurethane Adhesive Sealants

When using polyurethane adhesive sealants, preparation is key. Start by cleaning the surfaces thoroughly. Any dirt or grease will interfere with adhesion. Use a suitable cleaner to ensure a strong bond. Sometimes, it’s easy to overlook small residues. These can lead to failure later.

Once clean, apply the sealant evenly. A caulking gun works well for this. Too much sealant can create a mess. Too little might leave gaps. It's often a trial-and-error process. Don’t rush this step; a careful application will save you time and trouble later.

Remember curing time is essential. Patience is required here. Rush this process and you might regret it. Make sure the environment is suitable too. Temperature and humidity play a big role in how well the sealant adheres. Monitoring these factors can prevent unforeseen issues. Mistakes during application can be frustrating, but they are also learning opportunities.