Blog

How to Choose the Right Stainless Steel Wire Mesh for Your Needs?

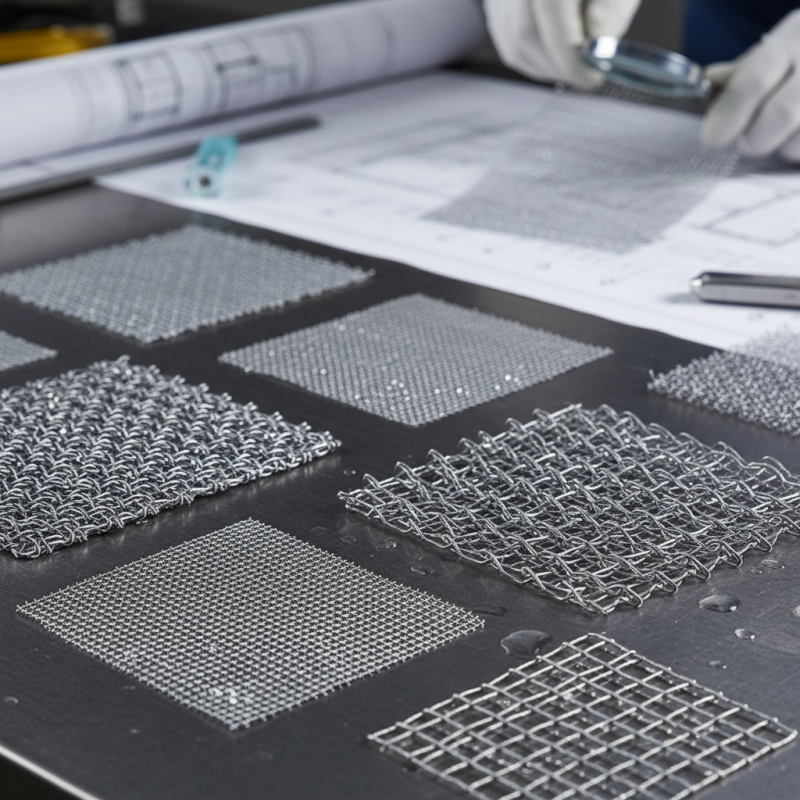

Choosing the right stainless steel wire mesh is essential for various applications. Whether for construction, filtration, or decorative purposes, the options can be overwhelming. Different grades and configurations of stainless steel wire mesh exist, each serving unique needs and environments.

Consider the strength and corrosion resistance you require. Each application has its specific demands, which can change based on surrounding conditions. A thick mesh might be suitable for heavy-duty use, while a finer mesh may be ideal for filtration.

Reflect on your project goals and requirements. It's not just about the specifications. Think about long-term performance and maintenance needs. stainless steel wire mesh can vary widely in price. Sometimes, opting for the higher quality pays off in durability. Be aware of your situation—do you need quick installation? Or is longevity your priority?

Understanding Different Types of Stainless Steel Wire Mesh Available

When selecting stainless steel wire mesh, it's essential to understand the various types available. Each type serves different purposes and offers unique benefits. For example, 304 stainless steel is the most common. It has good corrosion resistance and is often used in kitchen applications. Meanwhile, 316 stainless steel provides enhanced resistance to chlorides, making it ideal for marine environments.

Another option is welded wire mesh, known for its robust structure. This type is excellent for security features and fencing. On the other hand, woven wire mesh offers flexibility. It can be used in filtration processes or decorative applications. The mesh size also matters; finer mesh may be suitable for intricate projects, while larger sizes are better for strength.

Choosing the right type isn't always straightforward. Misunderstanding specifications can lead to poor choices. For instance, using weak mesh for structural purposes might result in failures. Availability and budget constraints can also narrow options. Reflecting on these factors can help guide your decision-making process effectively.

Key Factors to Consider When Choosing Stainless Steel Wire Mesh

Choosing the right stainless steel wire mesh can feel overwhelming. Various factors influence your decision-making process. Understanding these elements is crucial for making an informed choice.

One key factor is the mesh type. Different applications require specific mesh styles. For instance, welded mesh provides durability, while woven mesh offers flexibility. Both serve different purposes in industries and construction.

**Tips:** Analyze your project needs before selecting a style. Consider your environment, as certain types resist corrosion better than others.

Another critical aspect is the wire diameter. Thicker wires provide strength, while thinner wires offer better airflow. Balance your requirements with the potential downsides. A thicker mesh can restrict visibility while adding weight.

**Tips:** Assess the space where the mesh will be used. Ensure that visibility isn’t compromised. Sometimes, you may need to experiment with different diameters.

Finally, consider the mesh's opening size. Smaller openings can filter out unwanted particles, while larger openings allow for better drainage. It’s tempting to choose a size based solely on instinct. A quick reflection on your specific needs can help clarify your choices.

Analyzing the Specifications: Size, Gauge, and Opening Patterns

Choosing the right stainless steel wire mesh involves understanding specific details. Size is one of the main considerations. It refers to the dimensions of the mesh. A smaller size might be better for filtration. However, it can limit airflow. Larger sizes allow for better passing of air but might not filter small particles effectively.

Gauge is another important factor. This term describes the thickness of the wire. A thicker gauge provides more strength. It is suitable for heavy-duty applications. However, thicker wires may also be less flexible. This can hinder certain installation processes. Balancing strength and flexibility is key.

Opening patterns also play a significant role. There are various patterns like plain, twill, or dutch weave. Each pattern influences how the mesh functions. For instance, a twill weave offers dense coverage. Still, it might restrict visibility if used in decorative applications. Think carefully about how all these elements align with your specific needs. Reflect on the trade-offs. What works well in one case might not suit another.

Stainless Steel Wire Mesh Specifications Comparison

Evaluating the Corrosion Resistance and Durability of Wire Mesh

Corrosion resistance is crucial for stainless steel wire mesh. Many factors affect its performance over time. The environment where the mesh will be used plays a significant role. High humidity and exposure to chemicals can lead to faster deterioration. Stainless steel grades vary widely in corrosion resistance. Some may not perform well in salty or acidic conditions.

When selecting wire mesh, consider the specific applications. For marine environments, choose mesh with higher nickel content. This enhances resistance to saltwater. In industrial settings, exposure to harsh chemicals is common. Using a wire mesh designed to withstand these conditions is essential. It can save time and costs on replacements.

Durability is another key aspect. Look for wire diameter and weave density. A thicker wire often provides better strength. However, it may not be necessary for lighter uses. Balancing weight and durability is sometimes tricky. In some cases, thinner mesh can suffice for certain applications. Personal experiences with mesh selections can vary greatly. Testing in real conditions helps refine choices.

Application-Specific Considerations for Selecting Wire Mesh Solutions

Choosing the right stainless steel wire mesh involves understanding specific application requirements. Different industries have distinct needs that dictate the type of wire mesh suitable for their operations. For instance, filtration applications often require a finer mesh. Data shows that wire meshes with apertures smaller than 100 microns are commonly used in pharmaceutical and food industries. This fine mesh ensures the removal of particulates and contaminants.

In construction and architecture, durability is key. A thicker gauge wire mesh is necessary for load-bearing applications. Statistics indicate that wire mesh with a gauge of 10 to 16 is standard for reinforcing concrete. However, achieving the right balance between strength and flexibility can be challenging. Engineers often must consider environmental factors, as corrosion resistance becomes vital in harsh conditions.

While 304 stainless steel is popular due to its cost-effectiveness, its corrosion resistance may not suffice in coastal areas. In such instances, 316 stainless steel could be more suitable. These decisions can be complex. It is crucial to weigh the benefits against costs and intended use. Hence, understanding the nuances of application-specific requirements is essential in selecting the right stainless steel wire mesh.